OCEAN 3 AWARDED BEST WORKBOAT FENDERING SUPPLIER 2023

06 August 2024

Based in Linselles in nrthern France Ocean 3 has become globaly renowned as a high quality supplier of Marine Fendering and Navigational and Mooring Buoys.

Based in Linselles in nrthern France Ocean 3 has become globaly renowned as a high quality supplier of Marine Fendering and Navigational and Mooring Buoys.

It has a wide range of standard products to suit most practiceuses but can custombuild for every imaginable purposeif required. Ocean3's substantial Design Office and Factory maintains considerable stocks for immediate delivery.

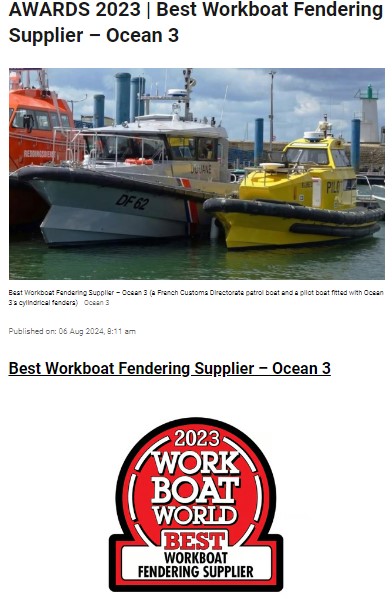

Its Fendering Systems are fitted worldwideto tugs, OSV's WFSV's, Ferries, Patrol Boats, Pilot Boats, Dredgers and every imaginable kind of Vessel as well as to Wharves, Jetties and Quays.

Our Fender Systemshave been known for more than 15 years now and for their efficient hull protectionattributes. Martin Wolczko, Head of Sales at Ocean 3 told BairdMaritime: We also undertake reliable calculations to design suitable Fender for a broad range of Vessel applications such as Oil & Gas Crewboats, Wind Farm Support Vessels, Pilot Boats, Patrol Vessels and even Bespoke Boats. Also high-quality materials are used to ensure efficient energy dissipationfor low reaction forces, thus distributing hull pressure and impact during berthing manoeuvres.

This year 2023 saw Ocean 3developp a new range of materials in collaboration with their Suppliers. This include Foams with greater resilience in absorption and 3D-reinforced fabrics designed to be encapsulated in tough abrasion-resistant coatings.

We are now turning to automation and incorporating it in some key parts of our manufactoring processes added Martin. This will help reduce some of the labour intensive steps in Production. We are also starting to consider the use of "green eco-friendly materials.

Martin said that 2023 was also a year of growth for Ocean 3, particularly in the Workboat Fendering segment as as evidenced by the approximately 300 Vessels being equipped with the Company's products. There continues to be great demand among Operators of Pilot Boats, Oil & Gas Crewboats and Wind Farm Support Vessels, though activity has also picked up in other market segments such as defence and security with Landing Craft and Unmanned Vessels requiring lightweight Fendering that also promises impact absorptionduring berthing.

"Because of our advanced designs and our production capabilities, we have generated even greater interestin Workboat Fendering Systems" Martin told Baird Maritime. Whereas rubber fenders were still widely used about two decades ago, "Composite Fenders"are becoming more common in various fields. We are also seing Foam Filled Fenders growing in number.

Martin added that in the future, electric Vessels and Unmanned Crafts will also require efficient hull protection. With Foam-Filled-Fenders now available, these can easily satisfy that requirement of such Vessels.