DONUT FENDERS

These fenders will follow same principles of Energy dissipation as our range of Ocean 3 "Foam Filled" Fenders and will be made from same materials. However the design and shapes will be different.

- Designed to bring back a Ship in her normal path

- Securing/enabling trickly manoeuvers in case of sudden tidal shifts

- Protect an area of grounding

- Corner or lock entrance protection

- Keeping a correct stand-off distance

- Development of an additional berth at low cost

- Shares the Energy absorption with the steel monopile

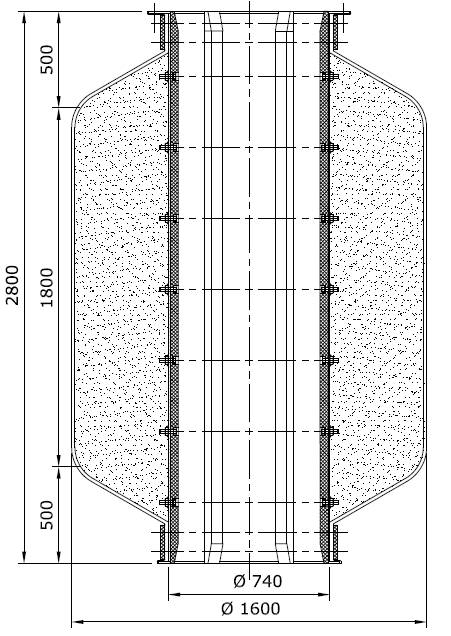

Ocean 3 Donut Fenders will provide a high Energy absorption for a low reaction force as with other foam filled fendering systems. It also has the ability to rotate around a steel monopile where large tidal changes occur with no high shear forces, by the mean of internal anti-friction UHMW bearing pads, even under compression; it gives the capability of changing the direction of Energy with no need to absorb all of it, just as a pulley.

Working out the specification of an Ocean 3 Floating Monopile Donut Fender is an important process. All aspects must be considered with a special emphasis on the design, involving simultanously consideration of both the pile and Donut Fender parameters. This as well taking into account features which should be checked to ensure an adequate design is developped : in view to ensure there is no contact between the Vessel and the pile at maximum impact loads, and to ensure a safe behaviour of the Donut Fender when in contact with the Ship during high winds or strong tidal surges.

Should Steel pile is also embedded on upper part, then Donut Fender will have to ensure the whole Berthing Energy in that case.

Materials

Ocean 3s' range of "Specific Fenders" are manufactured with the same high quality raw materials as its other foam filled products such Dock Fenders and Workboat fendering Systems :

- Cross-linked Polyethylen Foam with 100 % closed cells, densities ranging from 30 Kg/m³ to 140 Kg/m³ and sometimes higher, are used to manufacture Ocean 3 Specific Fenders, such as to propose the widest range of adequate products to consider all parameters of Energie absorption.

- Composite Coating based on High Abrasion resistance Polyurethane, reinforced with multiple fibers, thread layers or polyester textiles to ensure best hydrolysis behaviour. The coating thickness may vary from 10 mm to 50 mm and more according to targeted life span and considered strengths in the scope of work.

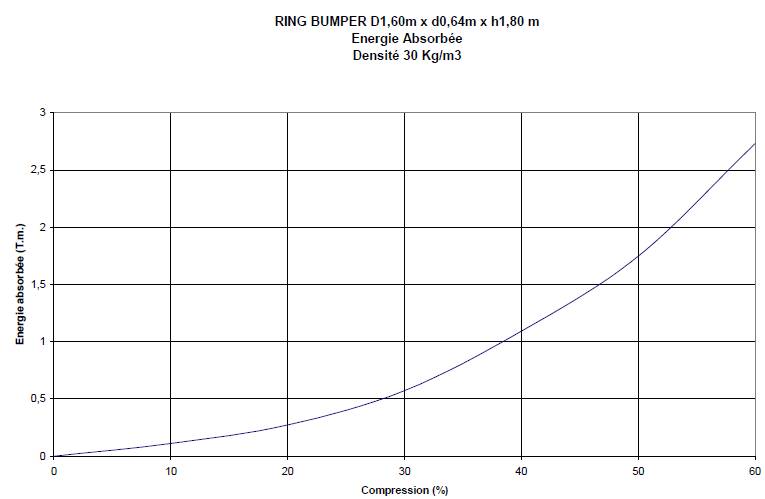

Energy Absorption

The below curve shows the Energy Absorption of the considered Ocean 3 Donut Fender under a different % of Compression. Only one side of the Fender is working during compression and not its entire diameter. Performances are usually given up to a compression of 60 % however higher compression is occasionally permissible during short periods of time when accidents occur.

A deflection at and higher than 75 % if applied over hours will reduce the ability of the foam to recover its original shape. It will however continue to insure its securing function. Please note that for such high compressions there is a risk of damaging the internal steel parts of the Donut Fender.

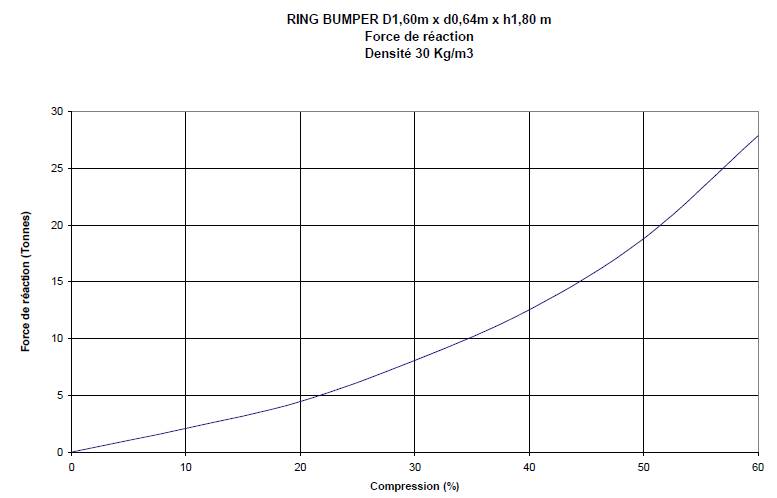

Reaction Force

The "Reaction Force" Curve shows the forces generated both on the Vessel hulls and the Steel Monopile during compression of the Donut Fender :

Performances

Fender performances are given at 60 % of compression; values may vary by +or- 10 % due to variations in speed of compression, operating temperatures, materials and dimensional tolerances. They are calculated by Ocean 3s' Design Department according to the specification of the Vessel and its operating conditions.

Lock entrance / exit corner fenders

- Designed for protecting Harbour entrances like docks, locks or as a guide to ships diverting from their normal paths

- Angled design which presents a softer feel in case of frontal impacts

- Longitudinal guide to straighten the Ship in its trajectory avoiding serious damages to hulls and jetty/Quay walls

- Sizes and Shapes are calculated taking into account the Vessel characteristics while reducing the width of the fender to a minimum

- Several fixation methods are available : For instance, the Fender can be glued on a steel plate, bolted on jetty/Quai wall; held by wires or chains and/or strapped